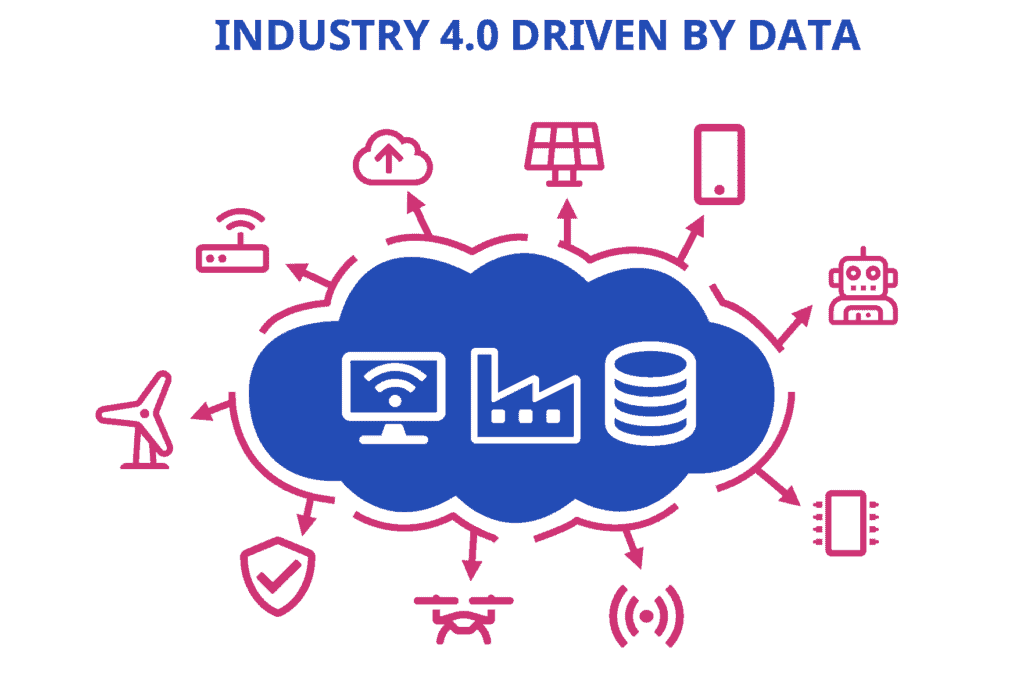

The Industrial Internet of Things (IIoT), 3D printers, artificial intelligence (AI), augmented reality and digital twinning (1) are enhancing business operations across manufacturers of all sizes from all sectors. The biggest operations can take full advantage of However, a large number of SMEs are still lagging far behind. Given the trend towards more customisation and the potential for smaller product runs, there are opportunities for smaller players to get in on the game. The main barrier for SMEs is lack of skills and knowledge, but financing is also a big obstacle at present.

To provide support for manufacturing SMEs looking into the routes to digitisation, the British government created its Made Smarter scheme. The pilot, rolled out initially in the North West saw a 20% take-up of small businesses in adoption of Industry 4.0 solutions. (2)