Apart from staple, high volume products, there is a lot of fragmentation of the FMCG market, as smaller players move into specialised niches. That’s partly why customers have more stringent demands for transparency of product information (for example ethically-sourced materials or ingredients, product origin, health information and product quality). Digitally enabled end-to-end traceability of the product journey allows for product data to be used for information available at point of sale via smartphone apps (for example). What’s more, RFID tags, QR codes and near field communication (NFC) utilises product data for smart labelling and lends itself perfectly to scaling and granular information down to individual product level.

Why FMCG Manufacturers should invest in product data management

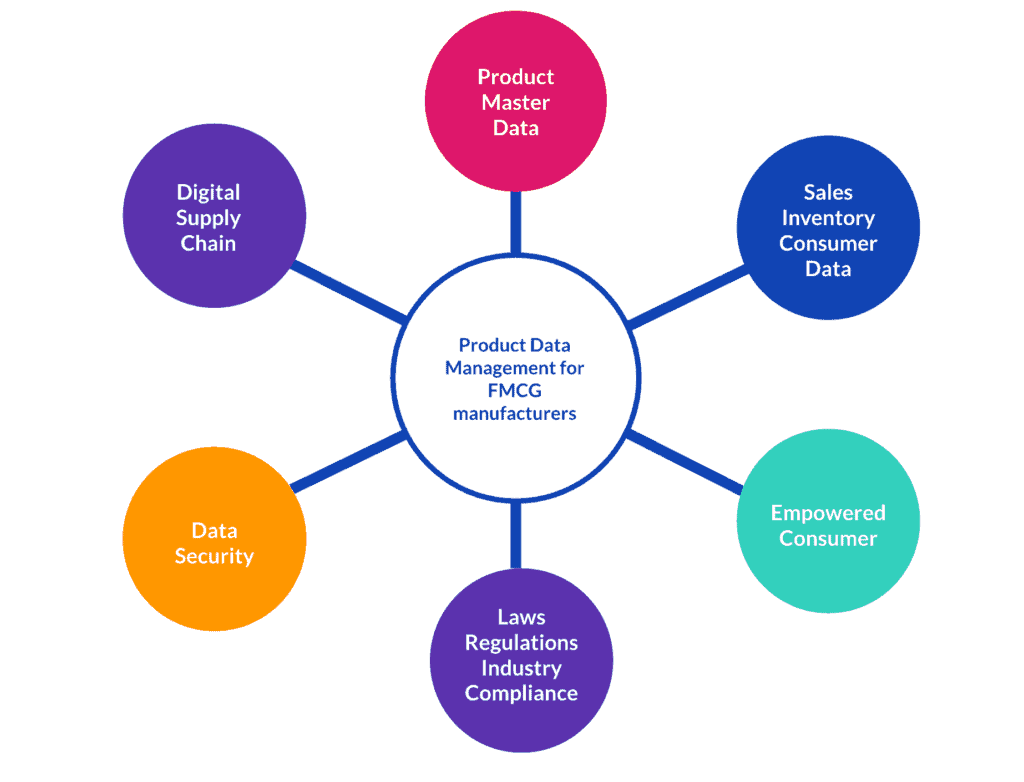

The current revolution in purchasing habits is being driven by digitisation, which is not only expanding its power in retail markets but also shifting the operating paradigm for FMCG manufacturers. Product data management is becoming key to their success as expectations regarding new product launches, extension of product ranges and time to market are becoming more and more demanding.

Industry 4.0 is a natural successor to what occurred in the late 20th century, where advances in IT and OT computerisation triggered big changes in retailing. The emergence of loyalty cards, back-office and logistics automation, lean supply chains, and the early iterations of eCommerce helped to create a new, more demanding customer profile. However, it is only now that the incremental results of technological innovations in this area have created a digital environment where companies have opportunities for end-to-end digital management of their value chain.

For FMCG manufacturers, the potential for exploiting product data is enormous. Big retailers manage vast data warehouses containing siloed information on loyalty, epos, and supply chain data to name three areas. Extracting, analysing and interpreting the data is challenging when many legacy technology stacks were not designed to manage such a large volume and variety.

The empowered customer

Download our free PIM Buyers Guide

FMCG product data management in the era of industry 4.0

The capabilities unleashed by digital supply-chain integration have allowed customers and companies to connect via cloud-based platforms. For example, the power of industry 4.0 is allowing food manufacturers to speed up the process of getting their products to market. How? By leveraging the technology to connect supply chains to their production facilities using interoperable and integrated product data management solutions. The power to identify and analyse patterns in the vast amounts of data they generate is also opening up opportunities for manufacturers to actually anticipate demand using machine learning for predictive analytics. This ability, in turn, enhances the development and fine-tuning of solutions in the manufacturing process.

The partnership potential for manufacturers and retailers

Manufacturers are also fast realising the potential of optimising their product data feeds to retailers. Interconnectivity throughout the value chain has never been greater and product data management is the pivot around which this cloud-enabled collaboration can best be exploited by all partners and stakeholders;

- by manufacturers themselves: as the information about their goods travels along the value chain to the end user, the consumer.

- by the distributor or retailer: the greater the amount and quality of product data they receive, the better they can internally manage their processes and workflows and the better the information which reaches the customer

- by the customer: they not only want but expect accurate, reliable, complete and trustworthy information about what they are buying. They also expect a seamless and consistent product experience whatever channel they use.

In the last decade, retail and consumer goods companies have mainly focused on their eCommerce customer interfaces. At present (and onwards), digital integration of the entire value chain is becoming an operational and strategic priority. As a recent white paper comments; ‘This includes digitisation of product and service offerings; developing innovative digital business models; digitisation and integration of supply chains; and adopting data and analytics as a core capability.’ (1) The retail and consumer goods sectors are rapidly embracing the digitisation and interconnectivity of products, business models, and value chains. In the short to mid-term, this revolution will impact greatly on the capacity of these companies to;

- Respond quickly and flexibly to consumer needs.

- Maximise revenue streams

- Reduce costs in manufacturing processes, supply chain management, inventory and distribution expenditure

Given that FMCG manufacturers are operating in an omnichannel environment, the added value of product tracking and complete supply chain transparency will result in an enhanced customer experience. That is, always assuming the manufacturers’ and distributors’ product data management systems optimise the massive volumes of information they have at their disposal.

Product data quality: the truth, the whole truth and nothing but the truth

By digitising the supply chain, FMCG companies have the capacity to connect supply, logistics, and distribution platforms using the ‘single version of the truth’ offered by a high-quality product data management system – that is, astutely managed sets of data to be used for integrated planning and execution across the organisation and in alignment with trading partners. In terms of information integrity and completeness, this element of Industry 4.0 is fundamental in ensuring interoperability and efficiency throughout the manufacturing supply chain’s critical impact areas.

Thinking holistically

FMCGs manufacturers need to consider whether they want to continue eliminating discrete weaknesses on a piecemeal basis or take the steps necessary to create a digital transformation which will leave their organisations ‘future-ready’. If managers continue with patching up existing technology stacks, they are missing out on an all-encompassing vision of an integrated transformation. This means deploying a robust product data management framework to exploit the capabilities of the manufacturing technology available.

A cloud-based PDM solution, fully integrated with all other enterprise resource-planning tools, is the key component underpinning the effectiveness of FMCG manufacturers’ strategies. Integration is the holistic vision of how technology can serve that strategy. If there is interconnectivity among all elements forming the support system to the business processes, analytics, sales, marketing, logistics, supply chain management and so on, benefits for FMCG manufacturers naturally follow: speed, quality, customer-focused, scalability and collaboration.